It's quite frustrating when you're faced with your favorite skincare product but the lotion pump refuses to work. The reason for a malfunctioning pump is usuall...

READ MORE-

-

It's quite frustrating when your newly purchased lotion pump won't pop up no matter how much you twist it. This is usually because the internal locking mechanis...

READ MORE -

The most frustrating thing about newly purchased skincare products is often the lotion pump that just won't budge. In fact, these pump heads are designed with a...

READ MORE -

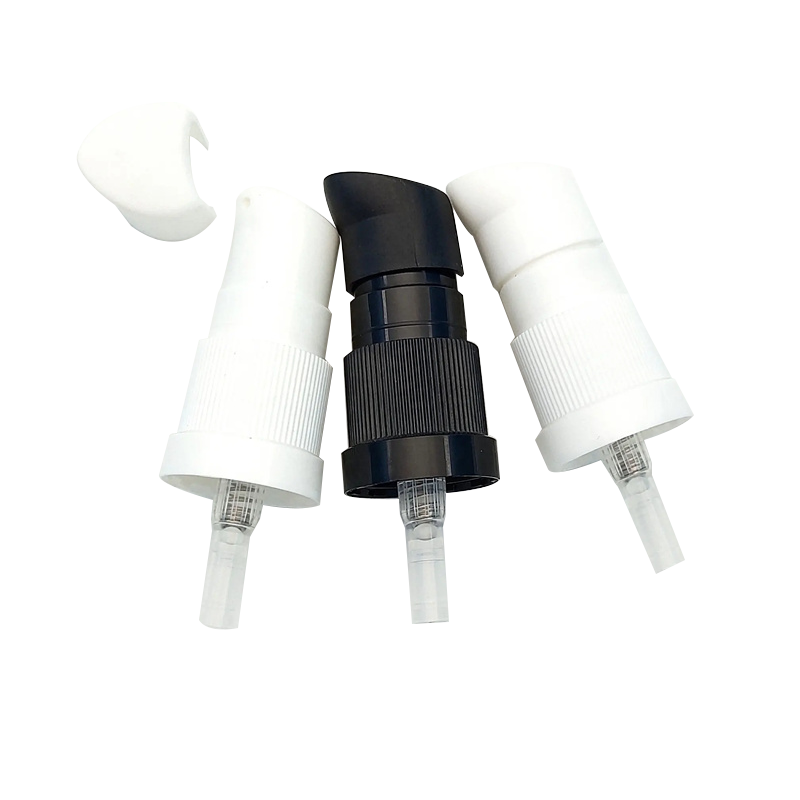

Although lotion pumps and soap pumps look very similar and are often used interchangeably, they have significant differences in their internal design and functi...

READ MORE -

The question of whether lotion pumps are recyclable, and whether we should recycle them, is actually quite an interesting topic.While most of the plastic bottle...

READ MORE

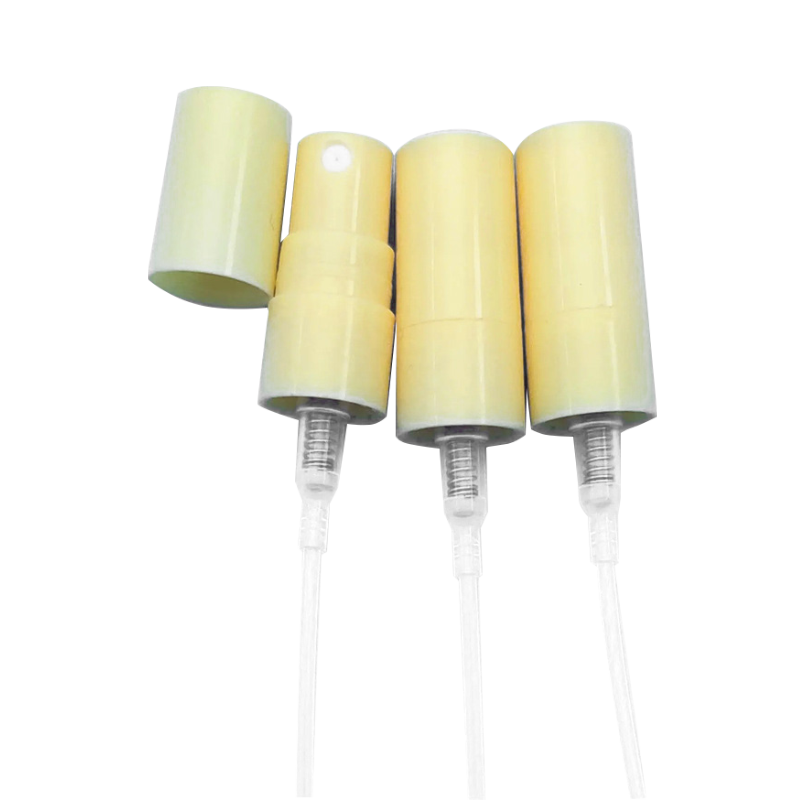

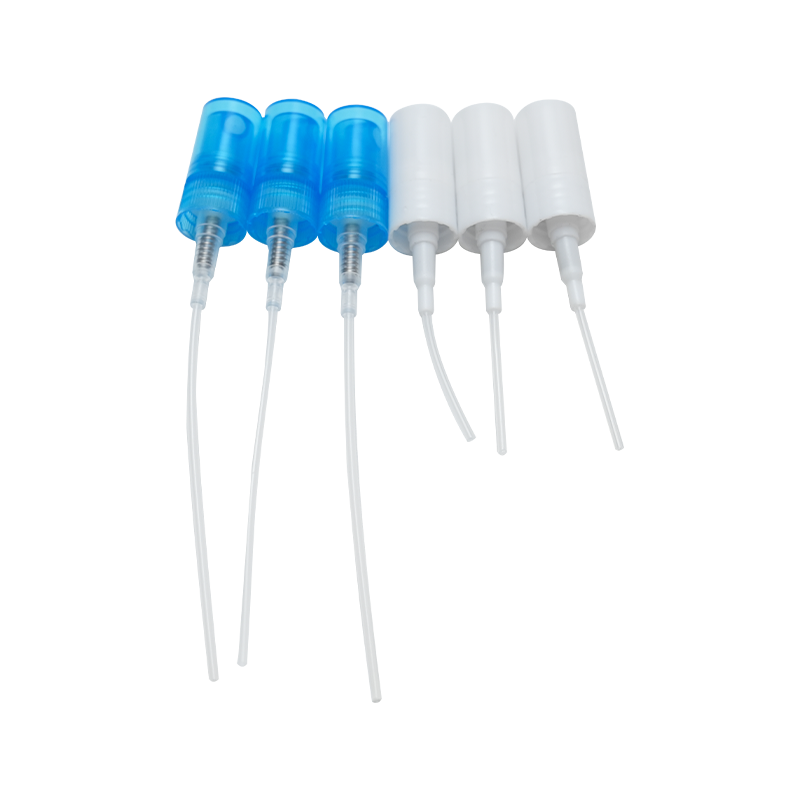

How to ensure the safety performance of 12mm Mist Sprayer in pharmaceutical packaging?

In the field of pharmaceutical packaging, safety performance is a crucial consideration. As a common form of pharmaceutical packaging, the safety performance of 12mm mist sprayer cannot be ignored.

First of all, the safety of materials is the basis. The 12mm mist sprayer used for pharmaceutical packaging must use materials that meet the standards of the pharmaceutical industry to ensure that they are non-toxic, odorless and pollution-free. These materials must undergo strict testing and certification to ensure that they will not have any adverse effects on the quality and safety of the drugs during contact with the drugs.

Secondly, sealing performance is crucial. Pharmaceutical products have extremely high requirements for sealing to prevent drugs from being contaminated and oxidized by the outside world. The 12mm mist sprayer should have a good sealing structure to ensure that the drugs are always in a sealed state during storage and use. At the same time, the selection of sealing materials should also take into account compatibility with drugs to avoid chemical reactions.

Furthermore, quality control of the production process is the key. When producing 12mm mist sprayer, the production specifications and quality standards of the pharmaceutical industry must be strictly followed. From the purchase of raw materials to the delivery of finished products, every link must be strictly tested and monitored to ensure that the quality and safety performance of the products meet the requirements.

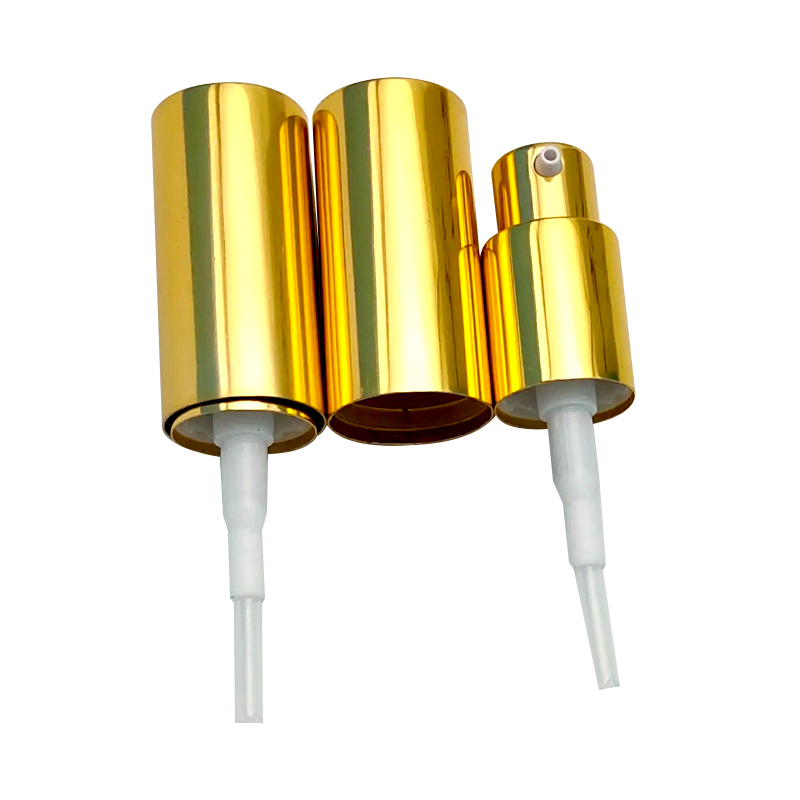

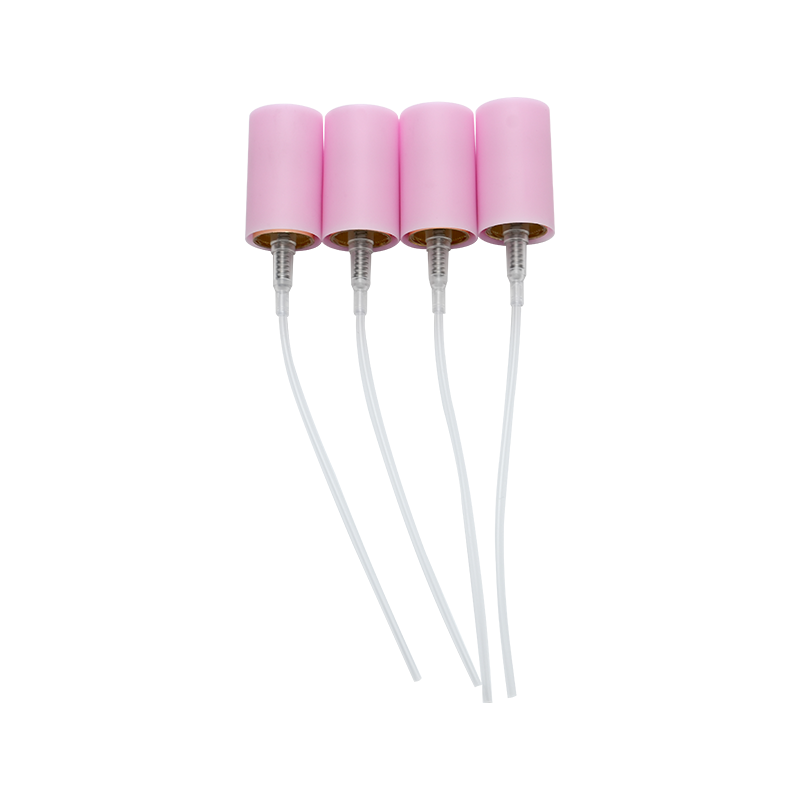

As a professional packaging material manufacturer, Zhangjiagang Haojie Packaging Technology Co., Ltd. has always put the safety performance of pharmaceutical packaging first. We use high-quality raw materials, introduce advanced production equipment and technology, and establish a strict quality control system to ensure that the 12mm mist sprayer we produce has excellent safety performance.

For pharmaceutical companies, choosing a reliable packaging supplier is an important measure to ensure product safety. Zhangjiagang Haojie Packaging Technology Co., Ltd. will provide safe and reliable packaging solutions for your pharmaceutical products with professional quality, strict quality control and high-quality services.

中文简体

中文简体 Español

Español عربى

عربى