It's quite frustrating when you're faced with your favorite skincare product but the lotion pump refuses to work. The reason for a malfunctioning pump is usuall...

READ MORE-

-

It's quite frustrating when your newly purchased lotion pump won't pop up no matter how much you twist it. This is usually because the internal locking mechanis...

READ MORE -

The most frustrating thing about newly purchased skincare products is often the lotion pump that just won't budge. In fact, these pump heads are designed with a...

READ MORE -

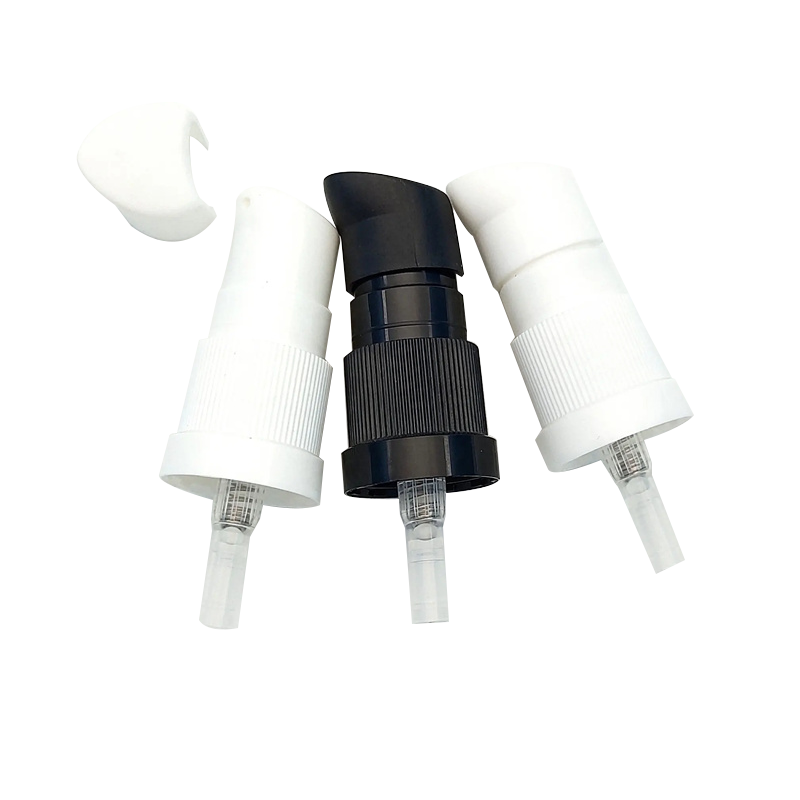

Although lotion pumps and soap pumps look very similar and are often used interchangeably, they have significant differences in their internal design and functi...

READ MORE -

The question of whether lotion pumps are recyclable, and whether we should recycle them, is actually quite an interesting topic.While most of the plastic bottle...

READ MORE

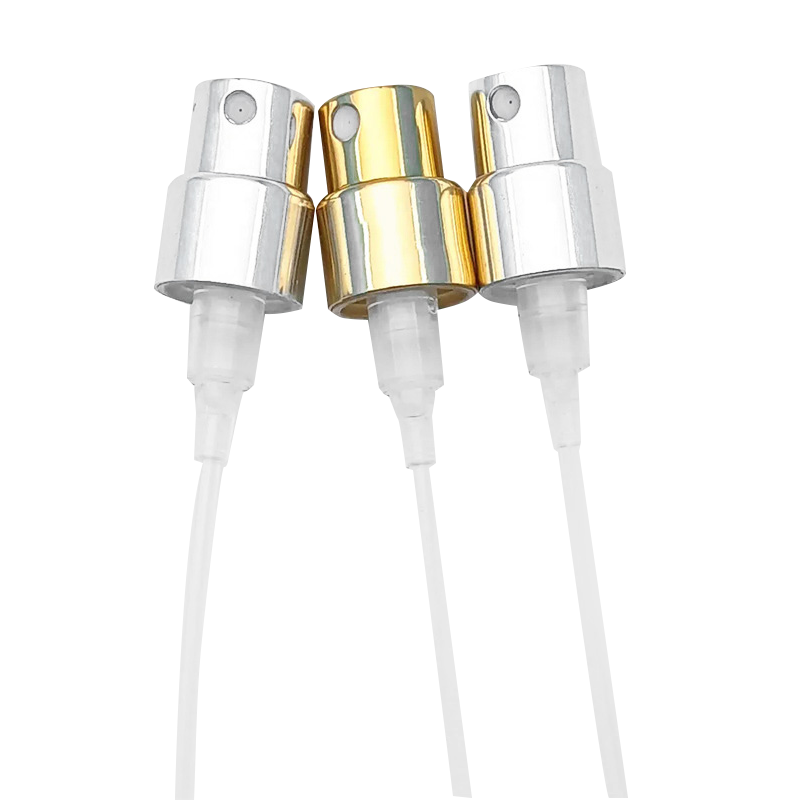

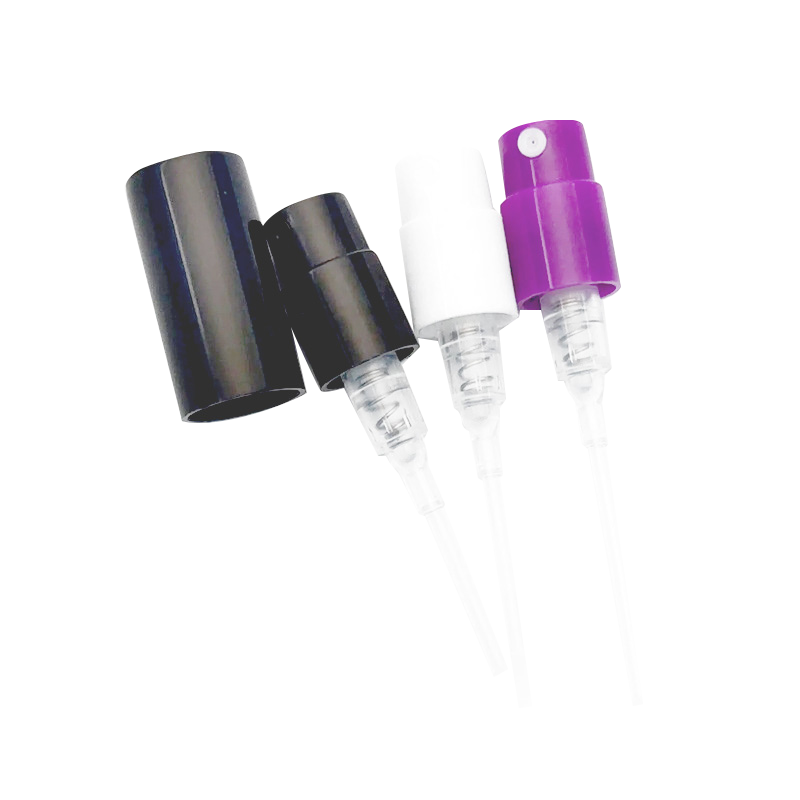

How to optimize the spray effect of 10mm Mist Sprayer in cosmetic packaging?

In the field of cosmetic packaging, 10mm mist sprayer has attracted widespread attention for its small and exquisite features. However, in order to give full play to its advantages, it is crucial to optimize the spray effect.

First of all, from the design point of view, the nozzle can be carefully designed. A reasonable nozzle shape and size can determine the particle size, spray angle and coverage of the spray. Through continuous experiments and improvements, the most suitable nozzle design for cosmetics can be found to ensure that the spray is uniform and delicate and can better cover the skin surface.

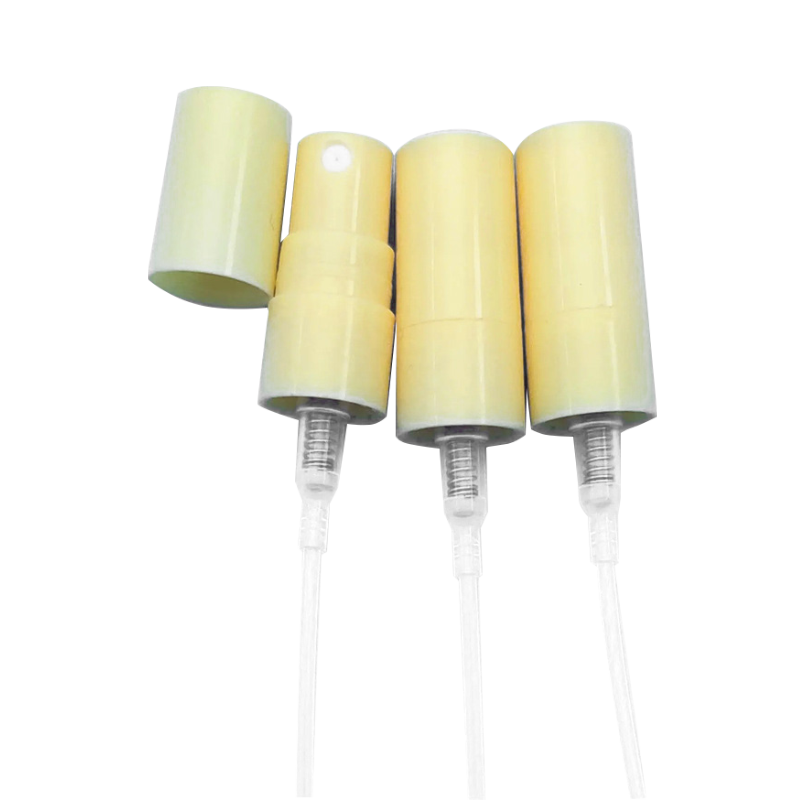

Secondly, the choice of materials also has an important impact on the spray effect. High-quality materials can not only ensure the durability of the mist sprayer, but also ensure the stability and consistency of the spray. For example, the use of corrosion-resistant and high-temperature resistant materials can avoid the chemical components in cosmetics from damaging the sprayer, thereby ensuring a long-term good spray effect.

Furthermore, the precision of the production process is also one of the key factors. Precise processing technology can ensure that the various components of the mist sprayer fit closely to avoid problems such as leakage or blockage. At the same time, strict quality control can ensure that each product has a stable spray performance.

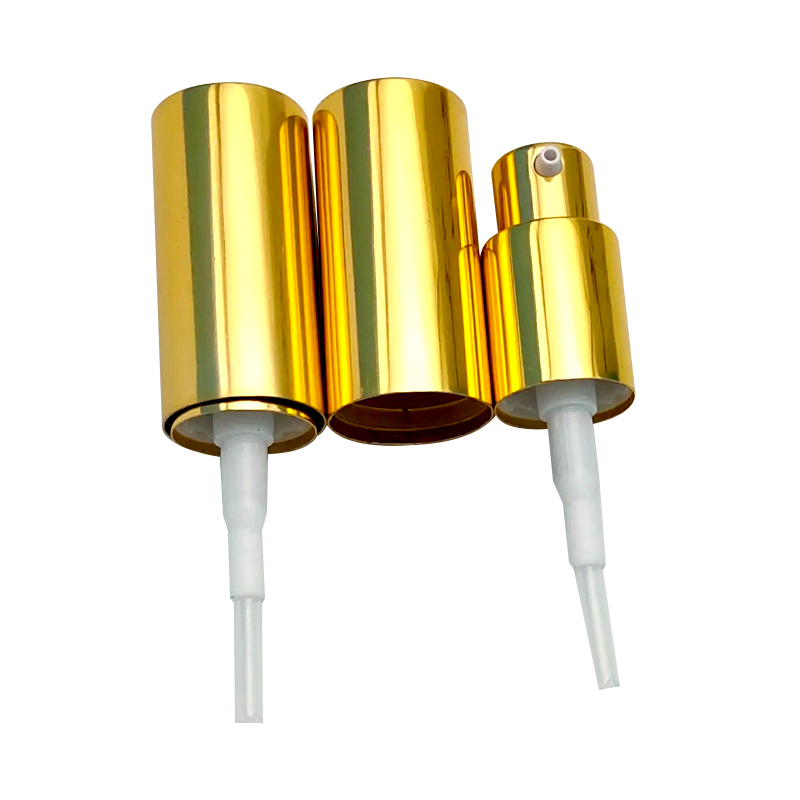

Zhangjiagang Haojie Packaging Technology Co., Ltd. takes these factors into full consideration when producing 10mm mist sprayer. We have a professional design team and advanced production equipment, and can customize mist sprayers of various specifications and performances according to customer needs. We pay attention to every detail, from the selection of materials to the control of production processes, and strive to do our best to ensure that our products have excellent spray effects.

For cosmetics brands, choosing a high-quality 10mm mist sprayer can not only improve the quality and image of the product, but also bring consumers a better use experience. Zhangjiagang Haojie Packaging Technology Co., Ltd. is your best choice. We will provide you with the most professional packaging solutions to make your cosmetics stand out in the market.

中文简体

中文简体 Español

Español عربى

عربى