What are plastic pump heads made of?

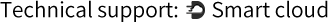

Industry News-Plastic pump heads are constructed from multiple components, each serving specific functional roles. Here’s a breakdown of their material composition:

1. Primary Casing & Body

Polypropylene (PP): Most common; resists chemicals (oils, alcohols), durable, and lightweight.

Polyethylene (PE): Used for softer parts like dip tubes; flexible but less rigid than PP.

Acrylonitrile Butadiene Styrene (ABS): For premium pumps; offers high gloss/shock resistance.

2. Internal Mechanisms

Springs: Stainless steel (rust-proof) or coated metal; provides recoil action.

Piston/Valve: Usually PP or thermoplastic elastomers (TPE); creates suction/seal.

3. Sealing Components

Gaskets & Seals:

Silicone: Heat/chemical-resistant; used in food/pharma pumps.

Rubber (EPDM): Flexible and low-cost; common in cosmetics.

TPE: Hybrid plastic/rubber properties; recyclable alternative.

4. Dip Tubes

Low-Density Polyethylene (LDPE): Flexible, transparent tubes that bend without cracking.

Polypropylene (PP): Stiffer tubes for thicker liquids.

5. Nozzles & Actuators

PP or ABS: Rigid enough to maintain spray pattern shape.

TPE/Soft-touch coatings: Added for ergonomic press comfort.

6. Specialty Materials

Chemical-resistant polymers (e.g., PTFE-lined) for industrial solvents.

Glass-reinforced plastics for heavy-duty applications.

Critical Material Selection Factors

| Component | Material Choice Drivers |

| Body | Chemical compatibility > Rigidity > Cost |

| Seals | Flexibility > Degradation resistance > FDA compliance (food/drug contact) |

| Spring | Corrosion resistance > Consistent tension > Longevity |

| Dip Tube | Flexibility > Clarity (to monitor liquid levels) > Kink resistance |

Material Limitations by Use Case

| Liquid Type | Avoid Materials | Ideal Materials |

| Essential oils | ABS, LDPE | PP, PTFE |

| Acids/bleaches | Metal springs, EPDM rubber | All-PP, silicone seals |

| High-alcohol | Rubber seals | Silicone/TPE seals |

中文简体

中文简体 Español

Español عربى

عربى