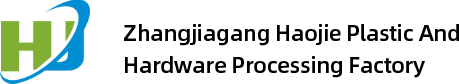

Is the pump head only vertical?

Industry News-Can Pump Heads Work Non-Vertically?

1. Standard Pump Heads: Vertical-Only

Gravity-Dependent Design: Dipependent Design: Dip tubes require liquid to pool at the bottle’s bottom. Tilting interrupts suction, causing air intake or dry pumping.

Failure Symptoms When Tilted:

Sputtering: Air bubbles mixed with liquid.

Incomplete Dispensing: Liquid trapped above the tube.

Leaks: Seals lose contact: Seals lose contact with the bottle neck.

2. When Limited Tilting Might Work (Temporarily)

High-Viscosity Liquids: Gels or pastes cling to tubes, allowing brief use at angles up to 45 degrees (e.g., squeezing out the last shampoo).

Near-Full Bottles:

70% full, slight tilting may not break suction immediately.

Hack for Residual Product: Lay bottle sideways, roll gently while pumping to coat the tube opening.

3. Special Pumps for Non-Vertical Use

| Type | How It Functions | Examples |

| Bag-on-Valve (BOV) | Collapsible bag pushes liquid out; no air needed | Inverted hairsprays, spray paints |

| Pressurized Systems | Propellant forces liquid out at any angle | Medical sprays, industrial cleaners |

| Angled Dip Tubes | Bent tubes reach liquid in tilted containers | Side-mounted soap dispensers |

4. Why Most Pumps Fail Horizontally

Suction Breakdown: Air enters the tube instead of liquid, breaking vacuum pressure.

Seal Failure: Pump collars rely on gravity to maintain bottle contact.

Foam/Lotion Pumps: Air-liquid mixing chambers malfunction, dispensing watery sludge.

5. User Tips for Problem Scenarios

Traveling with Upright Pumps: Use twist-lock features to prevent leaks, but store upright.

Emptying Bottles: Tilt bottle to 45 degrees max while pumping slowly.

Avoid: Storing standard pumps sideways – leaks guaranteed.

中文简体

中文简体 Español

Español عربى

عربى