What are the three common types of pumps?

Industry News-Content

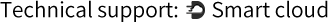

The Three Common Types of Lotion Pump Heads

In the packaging industry, the term What are the three common types of pumps? specifically refers to the locking and dispensing mechanisms used to secure liquids. The three most prevalent types are Screw-down pumps, Clip-lock pumps, and Switch (Twist-lock) pumps. Each is designed to prevent leakage during transit while providing a specific user experience during daily application.

Detailed Breakdown of Common Pump Mechanisms

1. Screw-down (Lock-down) Pumps

The screw-down lotion pump head is the industry standard for shipping security. To activate it, the user must press the head down and rotate it clockwise or counter-clockwise until it pops up. This design is highly effective at eliminating accidental discharge during heavy vibration in shipping containers.

2. Clip-lock (External Clip) Pumps

Clip-lock pumps feature a plastic "C-clip" or collar that sits between the head and the screw cap. This physical barrier mechanically prevents the pump from being depressed. It is a favorite for high-end aesthetic brands because the pump head remains in a "ready" upright position even before the first use.

3. Switch (Left-Right) Pumps

Also known as twist-lock pumps, these do not "pop up." Instead, the user rotates the lotion pump head 90 degrees to align the internal channel for dispensing. This type is ideal for shower products like shampoos and body washes where the user may want to re-lock the bottle frequently between uses.

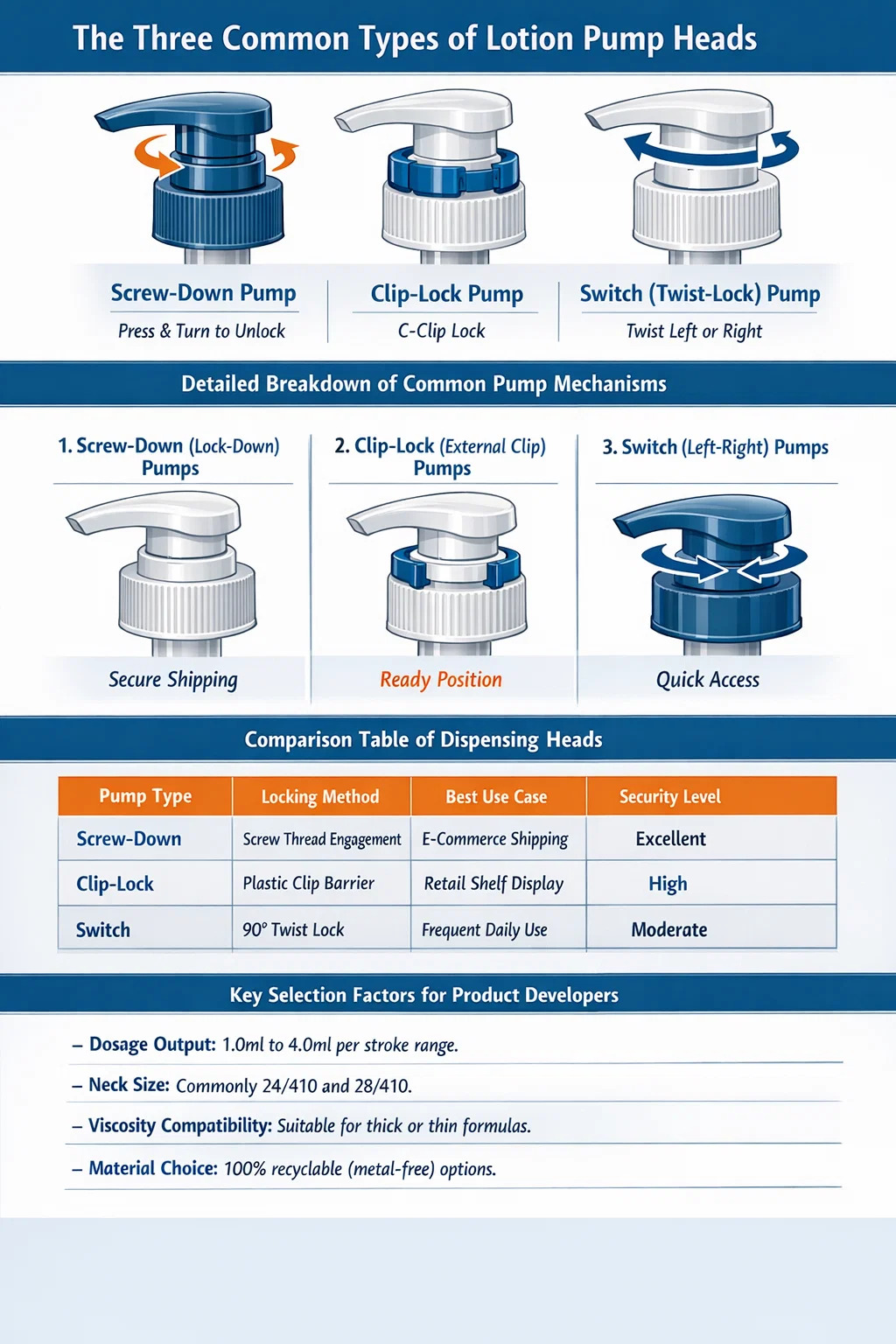

Comparison Table of Dispensing Heads

| Pump Type | Locking Method | Best Use Case | Security Level |

|---|---|---|---|

| Screw-down | Screw thread engagement | E-commerce shipping | Excellent |

| Clip-lock | Plastic clip barrier | Retail shelf display | High (Removable) |

| Switch | 90° internal alignment | Frequent daily use | Moderate |

Key Selection Factors for Product Developers

When choosing between these three types, consider the following technical specifications to ensure compatibility with your formula:

- Dosage Output: Most standard pumps deliver between 1.0ml to 4.0ml per stroke.

- Neck Size: Ensure the lotion pump head matches the bottle finish, commonly 24/410 or 28/410.

- Viscosity Compatibility: Heavier creams require a pump with a larger ball valve and stronger spring.

- Material Choice: For 100% recyclability, look for metal-free (mono-material) pump designs.

中文简体

中文简体 Español

Español عربى

عربى